With roller style jigsaw puzzle machines

In die cutting, a die is a template with sharp edges that is pressed by a machine to create a uniform shape on a thin material such as paper or fabric. Commercial die-cutting machines can be used for metal and other hard objects, but you can think of a home machine as a cookie cutter for crafting. The hand crank machine is easy to use and produces really lovely results for your next craft project.

Using a manual die cutting machine

1. Select the first design to be cut from the mold. Your die-cutting machine either comes with a set of dies, or there are compatible kits sold. No matter what type of material you want to cut, you’ll want to choose your first design from the mold of your choice. You may have several shapes to choose from; when deciding what shape to use, think about what you are making and for whom.

You can choose from flower shapes, hearts, stars, letters, spirals or animal shapes, depending on your stencil kit.

Also consider what materials you have available when designing your project.

2. Sandwich the mold and material between layers of foam. For things that are turned through the machine, follow the layered sandwich pattern. The base that comes with the machine will have a thick layer of rubber or foam. Place the paper or other thin material you want to cut on top, position the mold where you want to cut on the paper, and then lay another thick layer of foam on top.

Different machines may differ slightly. Follow the instructions on your specific machine to make the die-cut sandwiches.

Your machine comes with all the rubber or foam layers needed – you just provide the material you want to cut and select the mold from the range of molds.

3. Turn the crank slowly. Once you’ve assembled your die-cut sandwich, start turning the crank toward the press. A pallet of material will move through the press and a die will cut the paper or other material. If you are using paper, you may hear a cutting sound.

Continue turning the crank until the pallet is all the way through to the other side.

4. Check that the material is completely cut through. Gently lift the top layer of foam to see if your shape is completely attached to the paper or other material. If it does, and you can get the shape out of the rest of the paper, you’ve completed that section and can move on to new cuts based on your project.

If there are areas on your shape that are not completely cut and are still attached to your material, you will need to move it back through the press.

5. If you need to cut the shape again, turn the crank in the other direction. Instead of reassembling the layers of the sandwich, simply place the pieces back into their original positions and start turning the crank in the opposite direction. The press will make a second cut based on the first cut, hopefully keeping all the edges of the shape completely separated from the rest of the material.

You can continue to turn the die cut back and forth through the machine. However, if it takes too many passes to make the final cut, you may be using material that is too thick for your machine.

To explain what die cutting is first we need to understand what die cutting is. Well, a die is a component with sharp edges that is used to stamp or cut different products such as metal sheets, cardboard, leather, paper, plastic and so on, by applying a certain amount of force.

Therefore, stamping is the act of cutting precisely into geometric shapes in plates or sheets of different materials. All of these are the result of mechanical operations performed by a press or stamping machine.

The most significant advantages of die cutting are:

First , it can reduce the producing time.

Second , it facilitates the automation of tasks.

Third , it can help reduce costs and can produce the same product without losing quality.

The professionals at Die Cutting Center are here to answer any questions you may have about die cutting or how die cutting can help your business. Don’t worry it, please contact us for more information.

Our website is : https://diecutting.shop/

Die cutting remains in the shadows of its finished products. The engineering and design that goes into it and the skills of building and maintaining stations are shrouded with the convenience it brings through its produced objects— as it should be. Many of the products that we enjoy on a daily basis have gone through die cutting. But, what is this ‘die cutting’ is? What significance does it bring?

Die cutting is fundamentally the process of cutting any material through the use of industry-grade machine or a simple personal cutting equipment (for personal use). It is necessary to produce precise and clean-cut items in mass quantity. To make it easier and more relatable, think “cookie cutter.” Yes! It is like cutting your cookie doughs into those adorable shapes using a sharp cutter, known as a die or a specialized metal sheet with blades to cut through paper, cardboard, fabric, rubber, and more complex materials into the desired shape or form.

Depending on the type of die cutting machine used and the supplier, processes can vary. It does not, however, veer away from its very function. A rolling die presses materials through a running cylindrical mechanisms that enables you high-volume production. If you use a flatbed die, materials are pressed flatly against two opposing plates that’s as easy as stamping for increased work efficiency.

Jigscut Die Cut offers a wide variety of capabilities to meet your most challenging die cutting needs. From concept through installation, Jigscut Die Cut can partner with you to meet all of your tooling specifications. No matter what your industry , our tooling offers high-performance and maximum efficiency.

Click here to see more of our services: https://diecutting.shop/

In the print industry, die cutting is a process performed by a specialized machine to produce unique cutout shapes. Creative designs are turned into eye-catching cutout boxes, stickers, and many other items that highlight your product and promote your brand.

Think of a die cutter as a cookie cutter. The shape of the die is the exact shape that gets cut into the substrate. Simply put, it is a metal tool with a raised sharp edge for cutting. Dies come in a few different forms, including thin metal dies and steel rule dies. Steel rule dies are typically more durable and can cut thicker materials.

At Jigscut , we use many different types of dies that come in a wide variety of shapes, sizes, and styles. Each die is carefully selected or custom designed to meet individual project needs.

Know more : https://diecutting.shop/

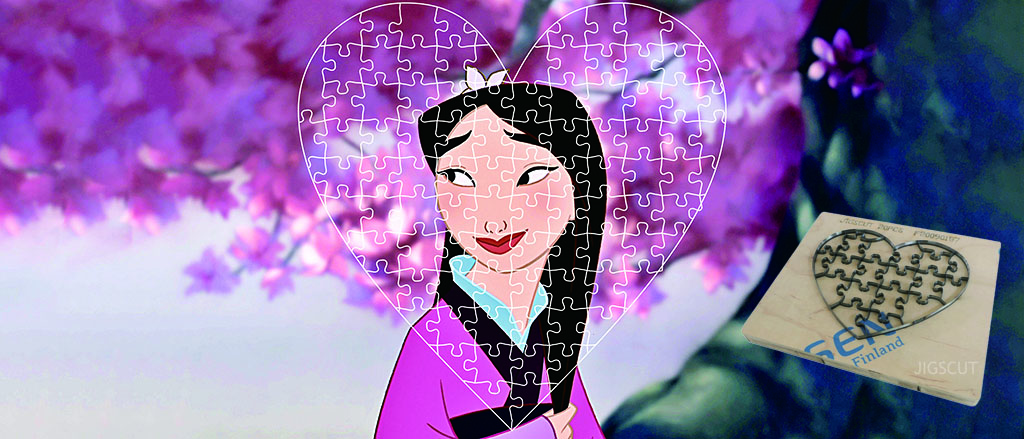

As a handcraft manufacturer, JIGSCUT can provide a variety of cutting dies , attracting people who love crafts.

From the perspective of the handcraft industry we are in, we hope that many people can continue to enjoy the joy of handcrafting. Our concept is to ‘make people around the world happy through handmade crafts.”

Today, the craft market is growing, with many people seeking relaxing activities to escape the hustle and bustle of daily life. Various initiatives are being taken to attract a more diverse population in order to be part of this growing market.

There are three important strategies here and one of them is to attract young people. We are trying to make our designs and products more attractive to them. We use social media sites such as Facebook to promote products that look and feel attractive to the younger generation. Second, we will develop and sell DIY-related products, etc., and strive to let more people enjoy the fun of handmade products. As much as possible. Third, in order to increase people’s access to handicrafts, we will export them all over the world, such as Europe and the United States.

According to the research , olders who regularly participate in word and number puzzles are found to have sharper brains .The more they play puzzles , the better their brain function becomes .

One study found that doing crossword puzzles could reduce the onset of dementia by two and a half years .This suggests that mentally stimulating activities may help delay the onset of symptoms , but they don’t by themselves prevent dementia . However , brain puzzles may be considered as part of a more comprehensive dementia prevention program that also involves exercise and healthy eating .

Here are some of the benefits of puzzles :

Improve short-term momory

Solving puzzles can strengthen the connections between brain cells , increase the speed of thinking , and it’s an effective way to improve short-term memory .

Enhance the mood

Puzzles increase the production of dopamine , a chemical that regulates mood , memory , and attention . When solve a puzzle , dopamine is released .

Make it easier to relax

While it’s tempting to relax by watching TV or reading on your tablet , the body should avoid looking at screens before bed . Puzzles provide a better opprtunity to relax , make it easier to fall asleep and switch off appropriately.

Improve visual and spatial reasoning

Need to look at the pieces of the jigsaw puzzle or the available sapce in the crossword puzzle and figure out how to fit the pieces or words into their spaces. If done regularly, this will improve your visual and spatial reasoning skills .

Relieve stress

With puzzles , can get the same benefits as meditation . The stress of daily life disappears and is replaced by a feeling of peace and tranquility , which lowers blood pressure and heart rate .

Improve logic and reasoning skills

Puzzles are designed to exercise the brain . Crossword puzzles , riddiles , word searches , and logic questions all activate different parts of brain and help you hone critical and analytical thinking skills .

Why not try a puzzle as a family and see for yourself the benefits?

A jigsaw puzzle is a type of jigsaw puzzle that requires the assembly of many small, usually odd-shaped, interlocking and inlaid pieces. Each piece usually has a small part of the picture; when completed, the puzzle will generate a complete picture. In some cases, more advanced types have appeared on the market, such as spherical puzzles and puzzles that display optical illusions.

The puzzle was originally created by drawing a picture on a flat rectangular piece of wood, and then using the puzzle to cut the picture into small pieces, hence the name. John Spilsbury, a cartographer and engraver in London, commercialized puzzles around 1760. Since then, puzzles have been mainly made of cardboard.

Typical images found in jigsaw puzzles include scenes from nature, buildings, and repeated designs. Castles and mountains are two traditional themes. However, any kind of picture can be used to make jigsaw puzzles; some companies propose to turn personal photos into jigsaw puzzles. The completed puzzle can also be attached to the backing with adhesive and used as a work of art.

In recent years, a series of puzzle accessories have appeared, including boards, boxes, frames and roller shutters, designed to help puzzle lovers. Some puzzle enthusiasts think that it is bad form (violating the rules) to look at the pictures on the box while the puzzle is in the puzzle, but most people think that it is completely normal to look at the box.

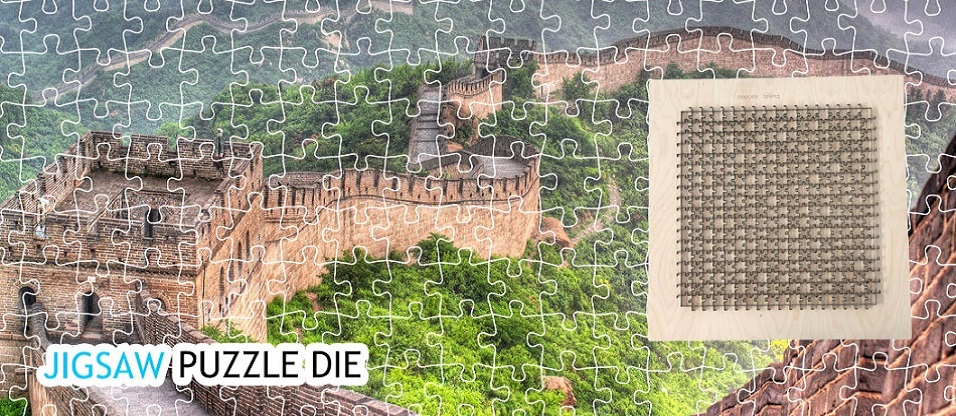

Most modern puzzles are made of cardboard because they are easier and cheaper to mass produce than original wooden models. An enlarged photo or printed copy of a painting or other two-dimensional artwork is glued to cardboard before cutting. The plate is then fed into the press. The press forces a set of hardened steel blades of the desired shape through the plate until it is completely cut. This process is similar to using cookie cutters to make special-shaped cookies. However, the forces involved are much greater. A typical 1000 piece puzzle requires a press, which can generate up to 700 tons of force to push the tool of the puzzle mold through the board. The jigsaw mold consists of a flat plate, usually made of plywood, with cut or fired grooves in the same shape as the knives that will be used. These knives are placed in the slot and covered on a compressible material, usually foam rubber, whose function is to eject the cut puzzle.

New technology makes laser cutting of wooden puzzles possible, which is a growing segment of the high-end puzzle market.

Many puzzles are termed “fully interlocking”. This means that adjacent pieces are connecting such that if you move one piece horizontally you move all, preserving the connection. Sometimes the connection is tight enough to pick up a solved part holding one piece.

Some fully interlocking puzzles have pieces all of a similar shape, with rounded tabs out on opposite ends, with corresponding blanks cut into the intervening sides to receive the tabs of adjacent pieces. Other fully interlocking puzzles may have tabs and blanks variously arranged on each piece, but they usually have four sides, and the numbers of tabs and blanks thus add up to four. The uniform-shaped fully interlocking puzzles are the most difficult, because the differences in shapes between pieces can be very subtle.

Some puzzles also have pieces with non-interlocking sides that are usually slightly curved in complex curves. These are actually the easiest puzzles to solve, since fewer other pieces are potential candidates for mating.

Most jigsaw puzzles are square, rectangular, or round, with edge pieces that have one side that is either straight or smoothly curved to create this shape, plus four corner pieces if the puzzle is square or rectangular. Some jigsaw puzzles have edge pieces that are cut just like all the rest of the interlocking pieces, with no smooth edge, to make them more challenging. Other puzzles are designed so the shape of the whole puzzle forms a figure, such as an animal. The edge pieces may vary more in these cases.

Since the earliest days of jigsaw puzzles the manufacturers have constantly endeavoured to create new cutting styles that differentiate their work. Even among modern, mass-produced puzzles there is considerable variation in the size, shape and intricacy of individual pieces.

The method of cutting pieces varies from puzzle line to puzzle line. Two puzzles of the same size and series from the same manufacturer usually have exactly the same cut, since the cutting dies are complex and expensive to make and so are used repeatedly from puzzle to puzzle. This enables disparate puzzles to be combined in odd ways. Larger puzzles are commonly cut into two or more sections.

More recently, technology such as computer controlled laser and water-jet cutting machines have been used to give a much wider range of interlocking designs in wood and other materials. These methods, however, have the undesirable effect of removing a small amount of material giving a loose fit with the adjoining pieces.

Beginning in the 1930s, jigsaw puzzles were cut using large hydraulic presses which now cost in the hundreds of thousands of dollars. The cuts gave a very snug fit, but the cost limited jigsaw puzzle manufacture only to large corporations. Recent the roller jigsaw Puzzle machine (https://www.alibaba.com/product-detail/Roller-style-Jigsaw-puzzle-machine-TYC30_60288780681.html?spm=a2747.manage.0.0.1f1c71d2lIwMJb) achieve the same effect, at a lower cost.

The most commonly-used approach to building a puzzle is to start by separating the edges from the inside pieces. Once the edges are connected it is easier to move inward. For those new to puzzles, it is recommended to choose one consisting of multiple areas with contrasting designs and colors. This enables the narrowing down of potential portions of the puzzle where a particular piece will fit.

One puzzle solving strategy is the use of the picture on the box as a guide. Once the edge is completed and the location of a particular piece is discovered (in the picture), it can be placed inside the overall puzzle at the approximate location it belongs. Done enough times and, eventually, interlocking the pieces will be possible.

Another approach is to sort the pieces by color, and work on one color at a time. When working large areas with the same color (such as the sky in many landscape puzzles), shape is important. All the pieces of a particular color can be laid in a grid and tried against other pieces in the grid.

Read more: http://jigscut.com/

Learn More : http://jigscut.com/

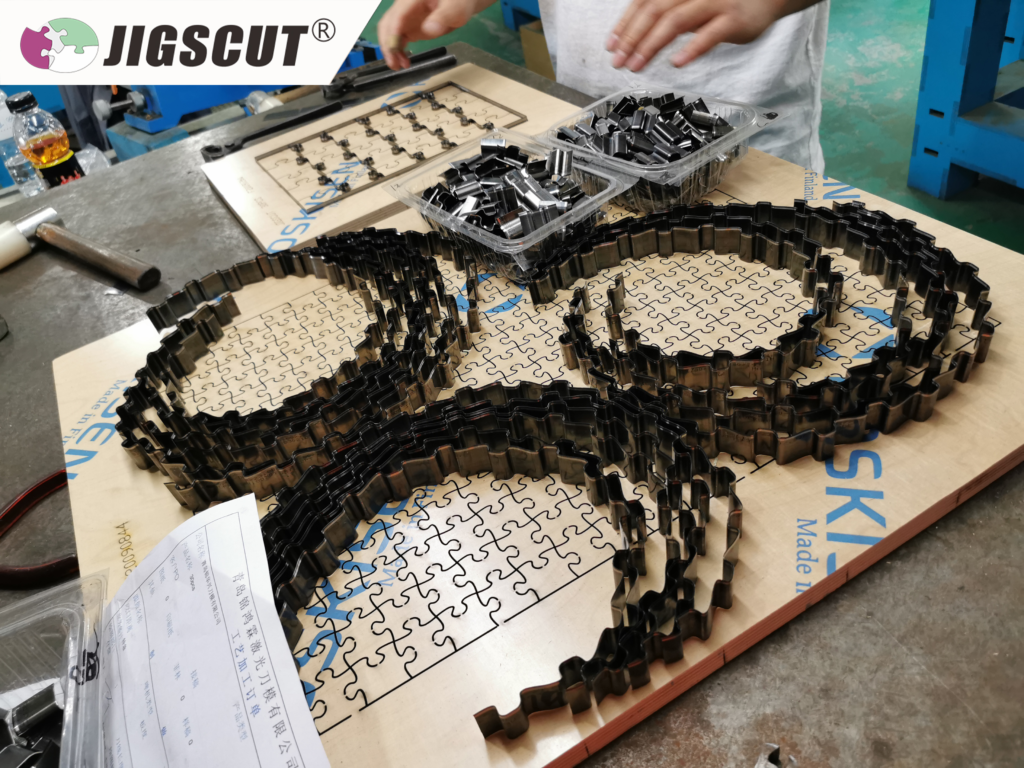

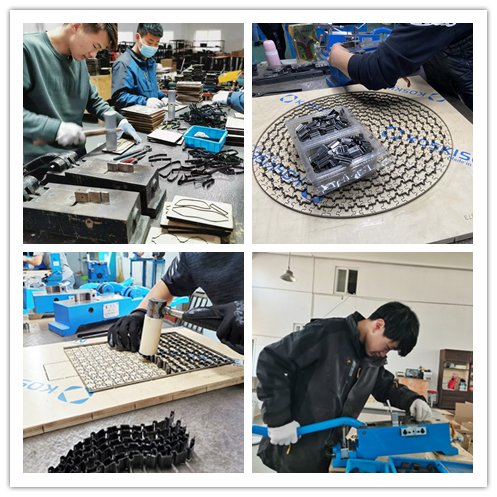

China-based manufacturer has come up with a rolling jigsaw puzzle machine that can be operated in the home. It’s perfect for sole proprietors and home-based businesses.

In addition to the puzzle machine and dies, all that’s needed is a computer, printer and occasionally a scanner (to adjust images). Jigscut offers steel rule dies for puzzle manufacturing companies and packing and printing industry and custom dies that can be used for scrapbooks and individual projects.

The rolling puzzle machine is simple enough to be set up in the home yet . It provides professional puzzles like the big manufacturers . Jigsaw puzzle dies produce puzzles from 2 to 3,000 pieces, so they can be marketed to all ages, they can be designed into most random designs, we have our designing teams on puzzles.

Jigscut wooden dies are also very durable. They can cut 20,000 times for the rolling puzzle machine, and last up to 100,000 times for professional puzzle press machines. Rolling puzzle machine and dies can also be used for custom projects made from a homemade photo, drawing or painting. You can basically do whatever you want and you can determine what image is to be used, the size of the puzzle and the number of pieces and design looking way. It’s great for making gifts that are really special.” Jigscut makes wooden dies for scrapbooking as well. These dies, which can be customized to individual orders, fit Sizzix and Accucut machines for a wide range of shapes and designs.

Learn More : http://jigscut.com/